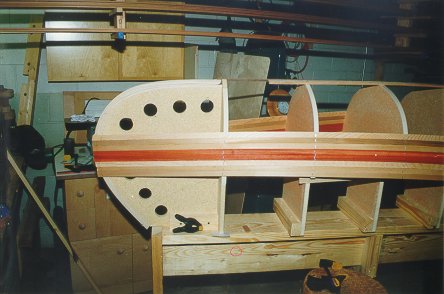

The holes in the form are there so that

the clamps have something to clamp the stems to.

The forms start to look good, much like

a skeleton.

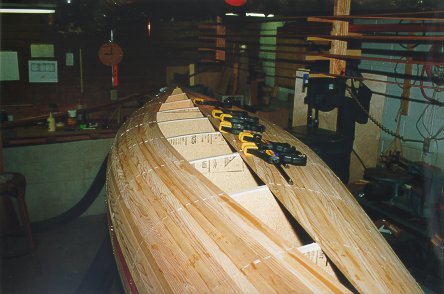

Placing the last few strips over the stems.

They will be trimmed and sanded later before the outer stem is applied.

This gives 1.5" of ash to protect the ends of the canoe.

Once the sides are on, you have to fit the

strips into the football sized opening. Cutting the strips for the center

is difficult.

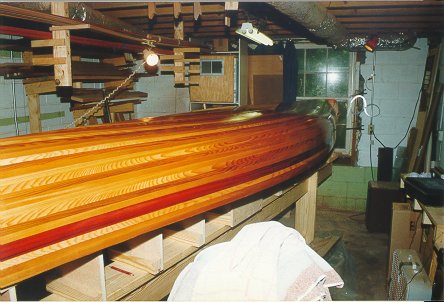

After adding the outer stem.

This is what it looks like with epoxy on

the wood.

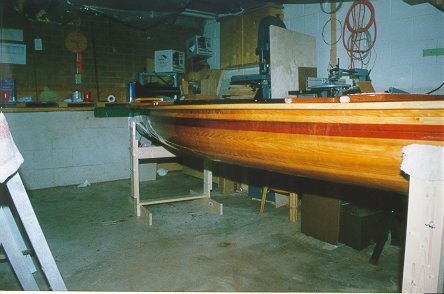

The outside has been sanded. The color will

return once the varnish is applied.

Once the canoe has expoy and fiberglass

on the outside, the canoe is taken off the forms. A few forms did not want

to break off even though I waxed all the forms.

Placing the fiberglass cloth inside the

canoe. Clothes pins are used to hold it up while the epoxy is applied.

Shaping the gunnels

Bending the gunnels. This did not work all

that well. Steam would have been better.

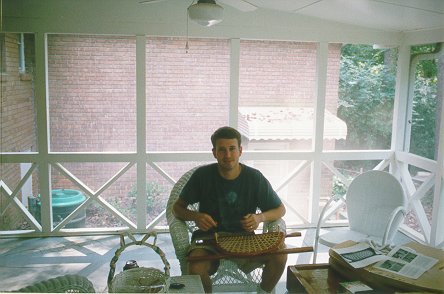

Weaving the seats. This took a few hours

but was well worth it.

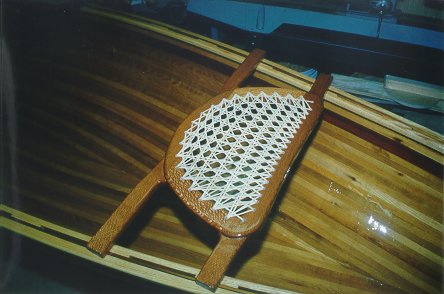

The completed seat.

The final product.